MAJOR PRODUCTS

We offer a wide variety of products that utilize the traits of cold forging,

Including high-rigidity, high-precision shafts, both short and long,

small diameter and large diameter.

Including high-rigidity, high-precision shafts, both short and long,

small diameter and large diameter.

Kaneta Kogyo quickly realizes the products your company requires, using our system that links cold forging products from development to production, and our unique knowledge accumulated over many years. In the automotive industry, which is entering a new age of international competition, how to gain an advantage on the market is an important issue. We contribute to solving various problems with our technical expertise, including cost competitiveness, as well as shortening lead time in order to meet the needs of the market in a timely manner.

Choose according to the application

Choose according to the product traits

Motor Shaft

- Processing/Machining : cold forging

- Traits : Completes INV.S with a length of about 78 mm by cold forging, and contributes to shortening the process.

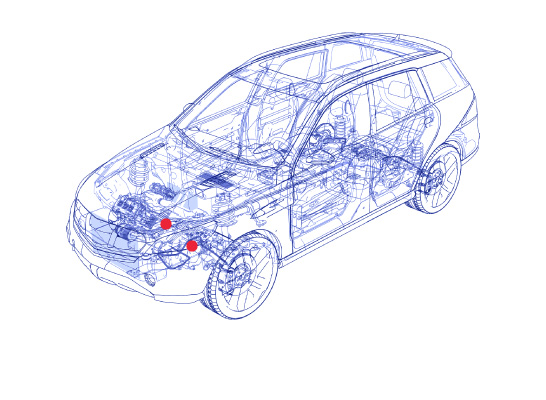

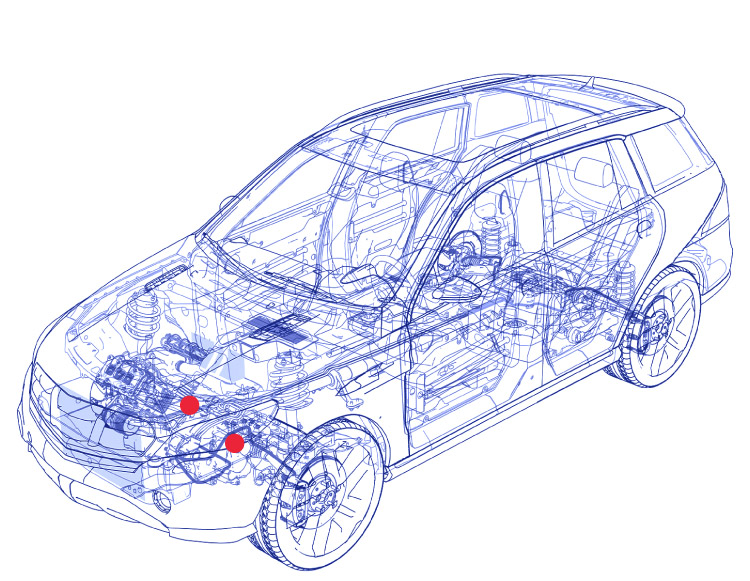

- Applications : 4-wheel vehicles shafts

- Size : φ59×190㎜

- Material : SNCM220

Generator Shaft

- Processing/Machining : cold forging

- Traits : Has a characteristic difference between the maximum diameter φ84 and the minimum diameter (φ26).

- Applications : 4-wheel vehicles shafts

- Size : φ84×260mm

- Material : SCR420

Hollow Molding

- Processing/Machining : cold forging

- Traits : Hole drilling and SPL molding are done by cold forging. It contributes to weight reduction and heat management.

- Applications : various shafts

- Size : Hole diameter × Depth, 5 times or more (one-shot)

- Material : SCM/SCR

Tooth Forging

- Processing/Machining : cold forging

- Traits : A helical gear with integrated shaft is formed by cold forging. Test results show that the maximum dedendum strength to tooth cutting ratio grows 2.5 times or more. Also, reduction in vibration value is observed.

- Applications : various shafts

- Size : (Ex.)Torsion angle 31.5˚, Module 2.6, Tooth width 55

- Material : SCM/SCR, etc.

Output Shaft

- Processing/Machining : cold forging

- Traits : Has a large CO2 reduction effect by reducing preparation weight, such as collar part molding and tip drawing.

- Applications : 4-wheel vehicles shafts

- Size : φ47×480mm

- Material : SCM420

Counter Shaft

- Processing/Machining : cold forging

- Traits : Spline molding 204 mm is complete with single process of cold forging forming.

- Applications : 4-wheel vehicles shafts

- Size : φ50×286mm

- Material : SCM420

Input Shaft

- Processing/Machining : cold forging

- Traits : Forges and forms the inner diameter spline. (Spline molding = bondless / no intermediate heat treatment)

- Applications : 4-wheel vehicles shafts

- Size : φ52×150mm

- Material : SCM420

Input Shaft

- Processing/Machining : cold forging

- Traits : The hole inside the shaft is formed by forging. Contributes to reduction of preparation weight.

- Applications : 4-wheel vehicles shafts

- Size : φ56×126mm

- Material : SCR420

Keyway Machining

- Processing/Machining : cold forging

- Traits : Keyway processing is done by forging and molding. Contributes greatly to process reduction.

- Applications : various shafts

- Size : Width: 7.5 mm, Depth: 4.0 mm, Length: about 250 mm

- Material : SCM/SCR, etc.

Axle

- Processing/Machining : cold forging

- Traits : Has a bearing surface, and the tip is hexagonally formed by forging.

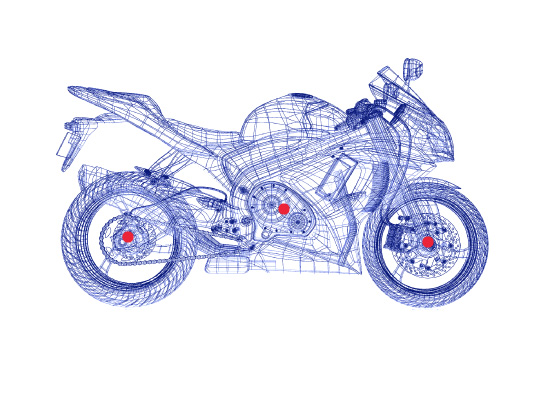

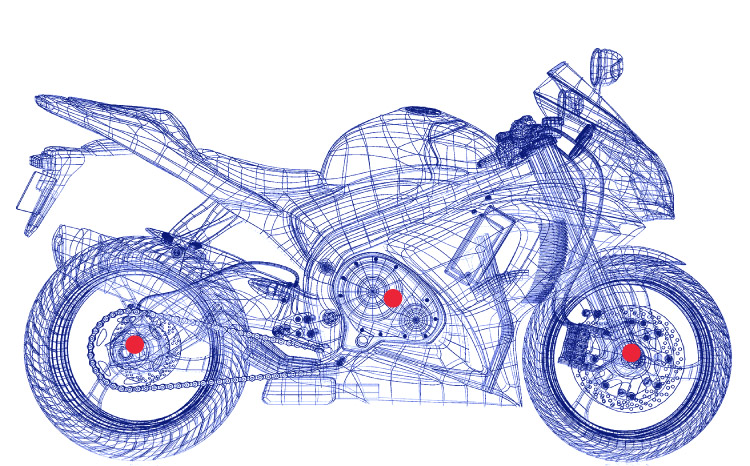

- Applications : 2-wheel vehicles

- Size : φ10×200mm

- Material : SCM435

Locker

- Processing/Machining : cold forging

- Traits : An example of processing and molding small items with cold forging. Hexagonal processing inside the shaft is also completed by cold forging.

- Applications : 2-wheel vehicles shafts

- Size : φ20×135mm

- Material : S40

Main Shaft

- Processing/Machining : cold forging

- Traits : A product subjected to gear processing by cold forging. Contributes to reduction of preparation weight and process.

- Applications : 2-wheel vehicles shafts

- Size : φ30×155mm

- Material : SCM420

Input Shaft

- Processing/Machining : cold forging, shaft cutting, rolling, drilling, carburizing, hard turning, washing

- Traits : About 1.5 times the finished weight vs. forged material weight. Contributes to reducing material costs.

- Applications : 4-wheel vehicles shafts

- Size : φ50×283mm

- Material : SCR420

Motor Shaft

- Processing/Machining : cold forging, shaft cutting, rolling, drilling

- Traits : φ26, hole depth 184 mm inner diameter processing.

- Applications : 4-wheel vehicles shafts

- Size : φ56×184mm

- Material : SNCM220

Motor Shaft

- Processing/Machining : bar cutting, cutting, rolling, keyway, carburizing, polishing, washing

- Traits : Shaft used in motors for electric vehicles. Forming of a boat-shaped spline.

- Applications : 4-wheel vehicles shafts

- Size : φ40×357mm

- Material : SCM420

Input Shaft

- Processing/Machining : cold forging, shaft cutting, rolling, drilling, carburizing, polishing, washing

- Traits : Complex hole drilling and clean parts with an impurity size of 0.16 mm2 or less.

- Applications : 4-wheel vehicles shafts

- Size : φ28×217mm

- Material : SCR420

Intermediate Shaft

- Processing/Machining : cold forging, shaft cutting, rolling, drilling, carburizing, polishing, hard turning, washing

- Traits : End face cutting after heat treatment. (Hard turning processing)

- Applications : 4-wheel vehicles shafts

- Size : φ46×236mm

- Material : SCR420

Input Shaft

- Processing/Machining : cold forging, inner diameter splining, shaft cutting, SP rolling, drilling, carburizing, polishing, hard turning, washing

- Traits : Inner diameter spline forming with cold forging.

- Applications : 4-wheel vehicles shafts

- Size : φ50×143mm

- Material : SCR420

Counter Shaft

- Processing/Machining : cold forging, shaft cutting, rolling, drilling

- Traits : Processing before heat treatment is also possible. Complex layouts inside holes are also possible.

- Applications : 4-wheel vehicles shafts

- Size : φ10×200mm

- Material : SNCM220

Parking Shaft

- Processing/Machining : bar cutting, induction hardening, polishing, washing

- Traits : Induction hardened carbon steel.

- Applications : 4-wheel vehicles shafts

- Size : φ18×86mm

- Material : S45C

Main Shaft

- Processing/Machining : cold forging, shaft cutting, rolling, drilling, carburizing, polishing, press fitting, washing

- Traits : Drilling done to a hole depth of 327 mm, diameter of φ12.

- Applications : 4-wheel vehicles shafts

- Size : φ34×386mm

- Material : SCR420

Motor Shaft

- Processing/Machining : cold forging, shaft lathing, SP rolling, drilling

- Traits : We do vertical drilling of holes with inside diameter of φ25.5 using gun drilling machines.

- Applications : 4-wheel vehicles shafts

- Size : φ55.3×185mm

- Material : HNCM220M

Generator Shaft

- Processing/Machining : cold forging, shaft lathing, SP rolling, drilling

- Traits : With cold forging, we form complex shapes with large diameter of φ83 and journal part of φ26.2. This improves material yield and reduces material costs.

- Applications : 4-wheel vehicles shafts

- Size : φ77.3×256.7mm

- Material : SCr420H

Input Shaft

- Processing/Machining : cold forging, shaft lathing, SP rolling, drilling, carburizing and quenching, grinding

- Traits : We do production of the same parts both in Japan and abroad.

- Applications : 4-wheel vehicles shafts

- Size : φ46.4×201.5mm

- Material :SCr420H

Input Shaft

- Processing/Machining : cold forging, shaft lathing, SP rolling, drilling, carburizing, grinding

- Traits : We do production of the same parts both in Japan and abroad.

- Applications : 4-wheel vehicles shafts

- Size : φ42.6×166.5mm

- Material : SCr420H

Final Shaft

- Processing/Machining : cold forging, shaft lathing, SP rolling, drilling

- Traits : We also accept semi-finished products.

- Applications : 4-wheel vehicles shafts

- Size : φ53×109.5mm

- Material : SCM420H

Main Shaft

- Processing/Machining : cold forging, lathing, rolling, drilling, gear grinding, carburizing, grinding

- Traits :The main shaft is incorporated into the manual transmission for motorcycles. We do gear grinding equivalent to JIS6 class.

- Applications : 2-wheel vehicles shafts

- Size : φ48.2×298.3mm

- Material : HSB415HV

Counter Shaft

- Processing/Machining : cold forging, lathing, rolling, drilling, carburizing, grinding

- Traits : The countershaft is incorporated into the manual transmission for motorcycles. Splining on the shaft is formed during cold forging, helping to improve material yield and reduce costs.

- Applications : 2-wheel vehicles shafts

- Size : φ38.6×206.3mm

- Material : HSB415HV

Axle Shaft

- Processing/Machining : cold forging, thread rolling, thermal refining, bending, surface treatment

- Traits : Capable of molding, by cold forging, up to a maximum length of 430 mm below the neck.

- Applications : 2-wheel vehicles shafts

- Size : φ17×318mm

- Material : SAE10B23M

Kick Spindle

- Processing/Machining : cold forging, lathing, rolling, drilling, punch marking, carburizing, grinding

- Traits : We search for splines with different numbers of teeth and stamp punch marks.

- Applications : 2-wheel vehicles shafts

- Size : φ18×95mm

- Material : SCM420H

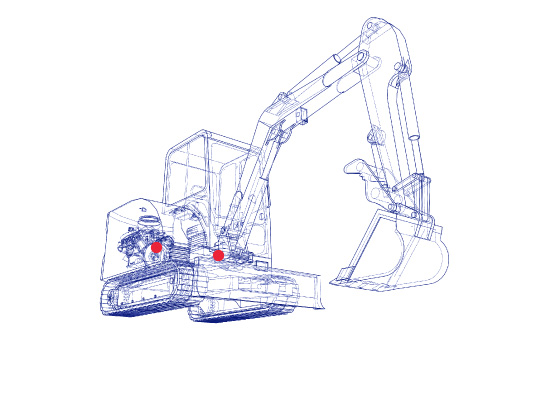

Drive Shaft

- Processing/Machining : cold forging, spline drawing, cutting, carburizing, polishing

- Traits : Draw forming by forging two splines.

- Applications : construction machinery

- Size : φ35×269mm

- Material : SCM420

Piston Motor

- Processing/Machining : cold forging, inner diameter splining, shaft cutting, carburizing, polishing, washing

- Traits : Inner diameter spline processing with cold forging.

- Applications : construction machinery

- Size : φ56×202mm

- Material : SCM420

Axle Shaft

- Processing/Machining : cold forging, lathing, rolling, carburizing, grinding, lapping

- Traits : We also manufacture shafts used in construction machinery.

- Applications : construction machinery shafts

- Size : φ42×235.3mm

- Material : SCM420H

Shaft

- Processing/Machining : bar material cutting, shaft lathing, drilling, carburizing, groove finishing, grinding, washing

- Traits : This shaft product is used in construction machinery. We integrate groove finishing and lathing done after carburizing.

- Applications : construction machinery shafts

- Size : φ42.5×191.2mm

- Material : SCM415H

Counter Shaft

- Processing/Machining : bar material cutting, shaft lathing, SP rolling, carburizing, grinding

- Traits : We respond to requests for general purpose equipment shafts which require various shapes and types with our high-mix low-volume production system.

- Applications : Snowbrower, Cultivator, etc.

- Size : φ15×55mm

- Material : SCM420H

Idle Shaft

- Processing/Machining : bar material cutting, shaft lathing, carburizing, grinding

- Traits : We finish the shaft center and tips with a grinding process.

- Applications : General purpose machine.

- Size : φ14.0×55.0mm

- Material : SCM420H

Counter Shaft

- Processing/Machining : bar material cutting, shaft lathing, gear grinding, groove cutting, carburizing, grinding

- Traits : We do hexagonal splining of the shaft center and JIS conforming splining.

- Applications : General purpose machine.

- Size : φ22.0×65.0mm

- Material : SCM420H

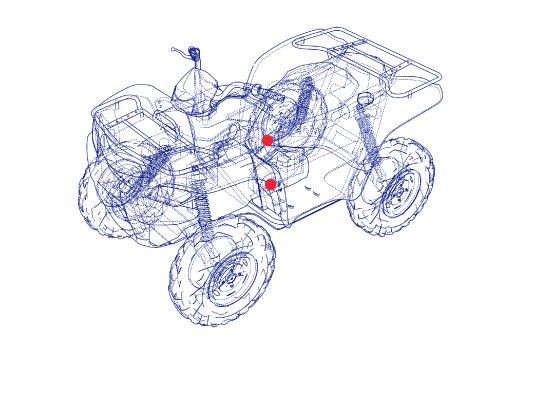

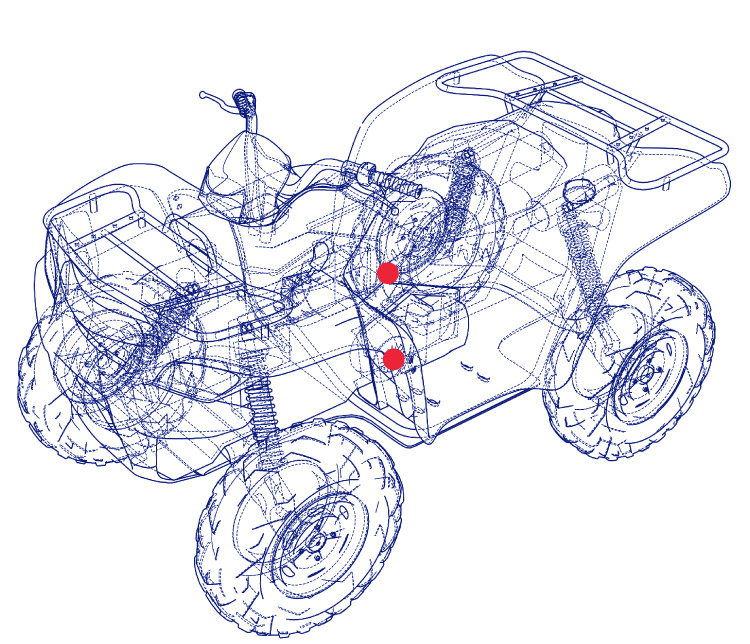

Outer Ring

- Processing/Machining : hot forging, cutting, broaching, carburizing, inner diameter polishing

- Traits : Inner diameter spline processing and outer diamenter pulsar processing.

- Applications : ATV

- Size : φ75×100mm

- Material : SCM420