VA/VE PROPOSAL We can optimize all processes with integrated cold forging production

Contact Kaneta

to reduce costs!

We realize VA/VE by optimizing all processes,

which ispossible because of our

in-house integrated production.

to reduce costs!

We realize VA/VE by optimizing all processes,

which ispossible because of our

in-house integrated production.

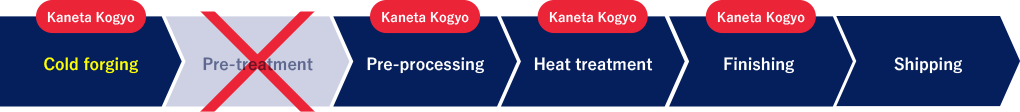

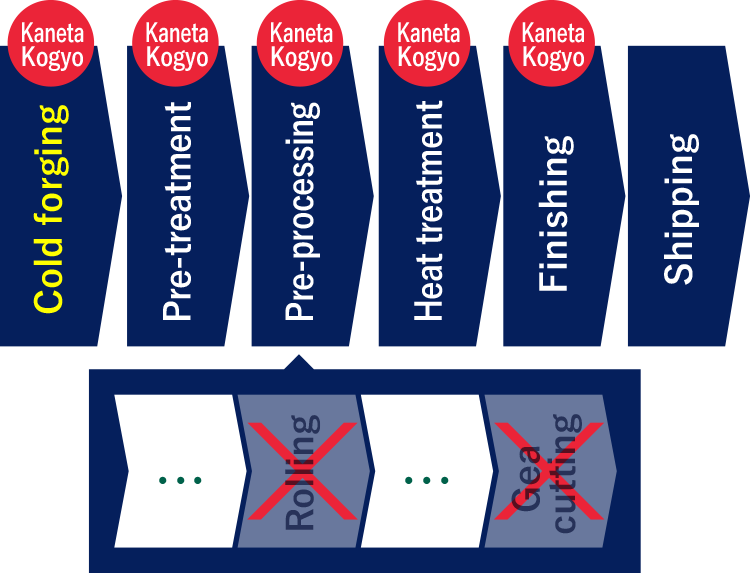

KANETA handles everything from material processing by cold forging to post-processing and finishing in-house.

VA/VE fully uses the strengths of our integrated system to achieve high added value in all QCD aspects.

VA/VE fully uses the strengths of our integrated system to achieve high added value in all QCD aspects.

This is what makes Kaneta’s integrated system different!

- Near net shaping reduces processing and material costs

- Information gathering and feedback from each process is fast

- We optimize the entire process to achieve further cost reductions

CASE 01

With our in-house integrated system we achieve both cost reduction and quality improvement

Processes that were previously distributed among multiple specialist companies are consolidated into Kaneta’s integrated production!

We achieve the same or better quality as conventional products at lower cost and shorter delivery times.

We achieve the same or better quality as conventional products at lower cost and shorter delivery times.

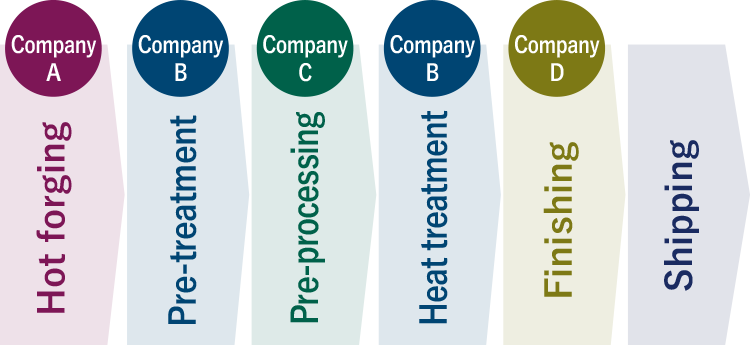

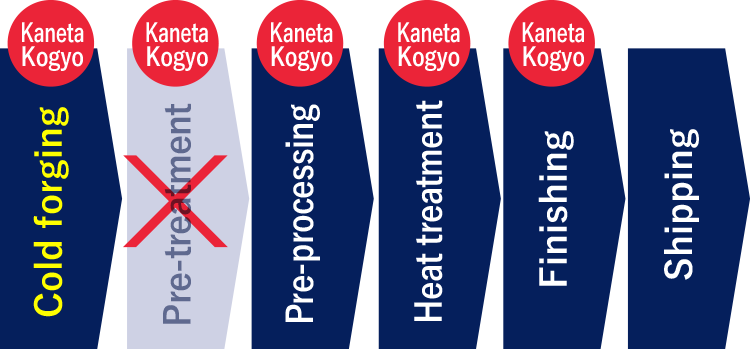

VA/VE example with cold forging and in-house integrated production

Currently

Multiple companies are in charge of processing. Just moving the product incurs costs and time.

Kaneta’s VA/VE proposal 01

By sharing information about the overall process status within the company, we shorten the maturation time of shaft products, including quality.

Kaneta’s VA/VE proposal 02

Further cost reductions can be achieved by selecting steel materials that do not require pre-heat treatment.

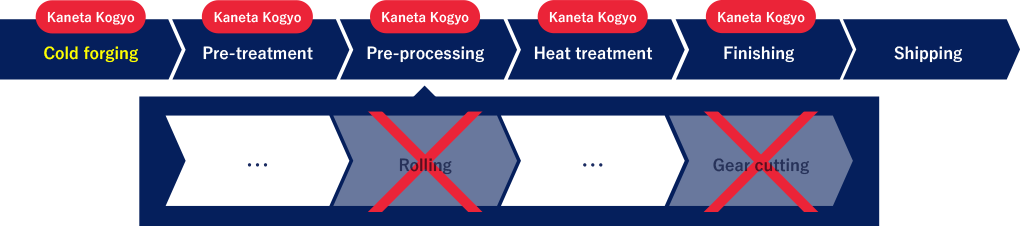

CASE 02

Cold forging makes it possible to consolidate and reduce processes

The rolling and gear cutting processes, which were previously separate processes, can be formed in one shot with cold forging.

By streamlining the processing process we allow for significant cost reductions and shorter delivery times.

(*Proposals vary depending on the product shape, spline position, and precision.)

By streamlining the processing process we allow for significant cost reductions and shorter delivery times.

(*Proposals vary depending on the product shape, spline position, and precision.)

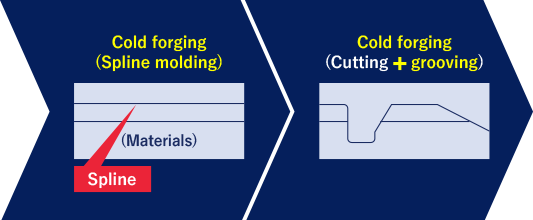

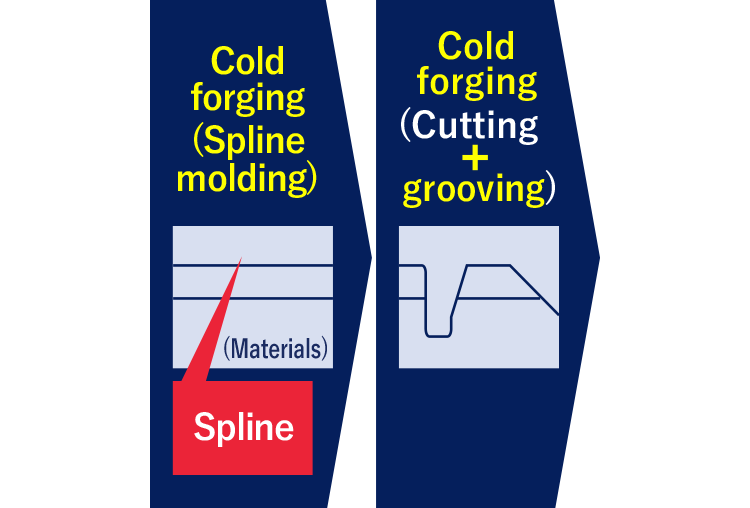

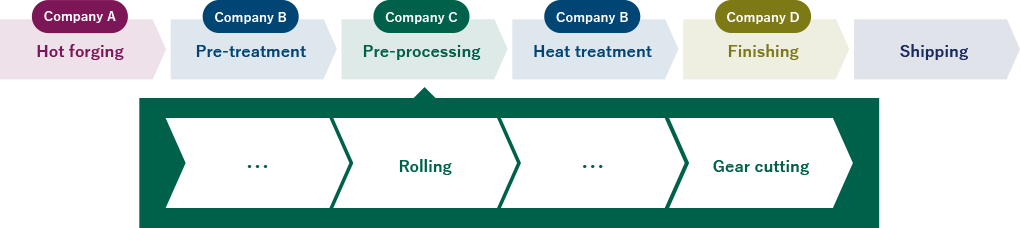

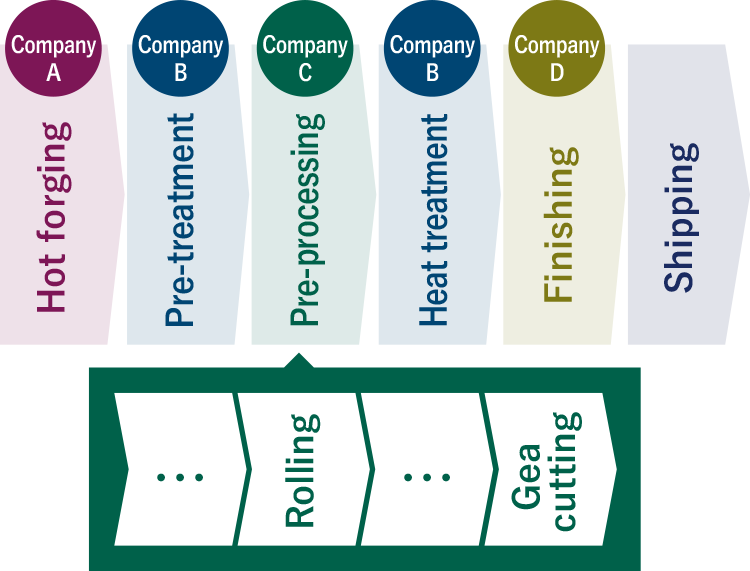

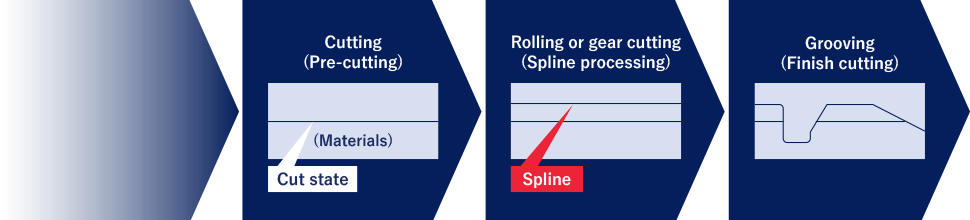

Example 01 of consolidating processes with cold forging

Conventional

Materials produced by hot forging are processed by rolling and gear cutting to produce.

Kaneta’s VA/VE proposal

By forming gears and splines with cold forging, it is possible to reduce machining processes

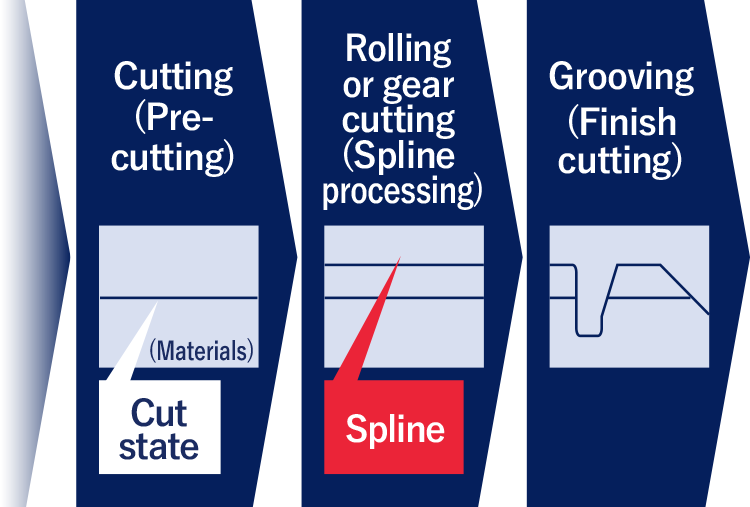

Example 02 of consolidating processes with cold forging

Conventional

For products with grooves in the spline, the process is generally cutting → spline processing → grooving

Kaneta’s VA/VE proposal

Through collaboration with cold forging, we have consolidated the process of the spline!