HEAT TREATMENT

With the FC method optimized for cold forging

we draw out the potential of the patented "Tooth precision Forging" technology.

What is needed to maximize the potential of tooth precision forged helical gears? Of course, it is heat treatment technology. The "FC method KANETA ver ." is a carburizing and quenching method that minimizes the variation in heat treatment quality within and between lots, and also minimizes the variation in hardened layer depth within a single unit.

Hardened layer variation is reduced to the utmost limit, achieving durability beyond the design.

The tooth precision forged helical gear is an original technology of Kanta Kogyo. The secret of its strength is not only fiber flow. The surface properties are obtained by cold forging. Only the uniquely evolved KANETA ver. FC method batch type atmosphere carburizing can utilize this and add further strength.

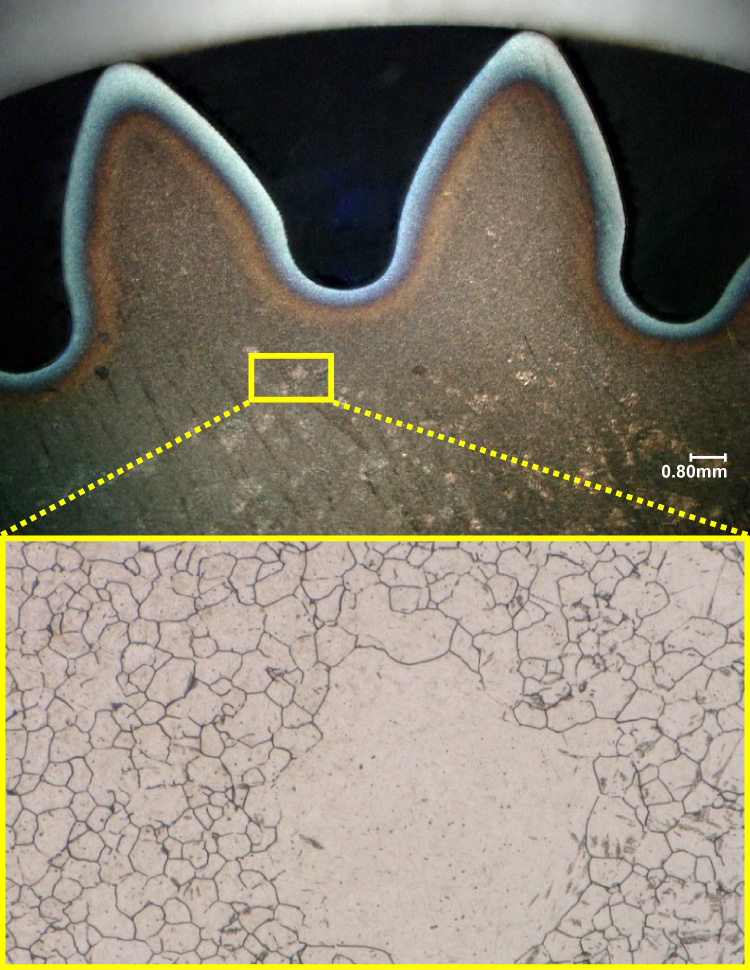

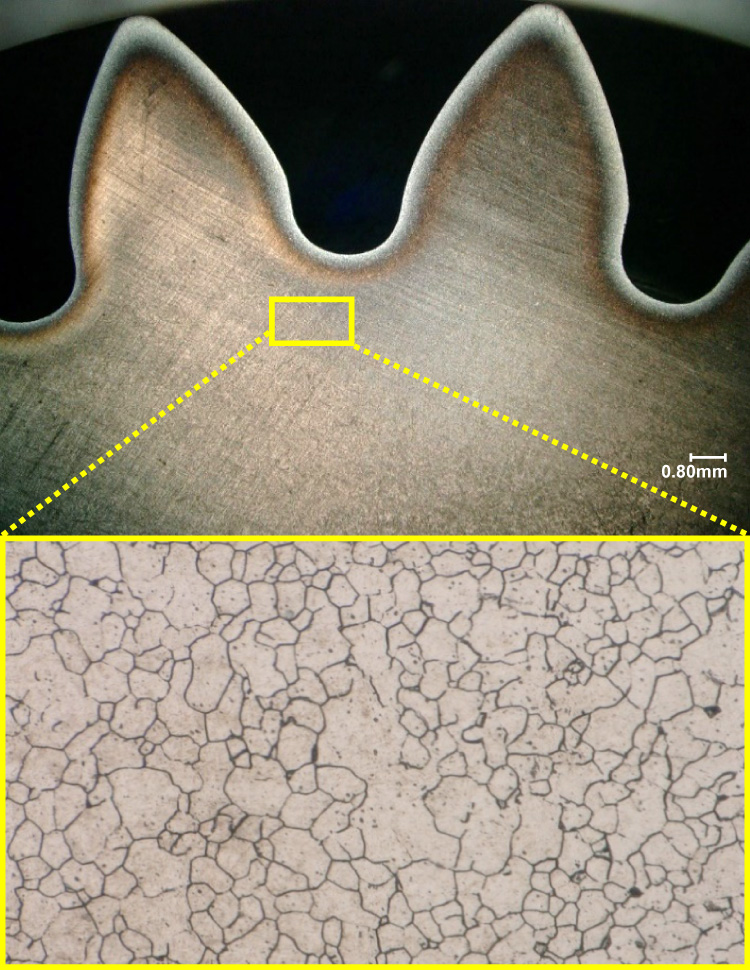

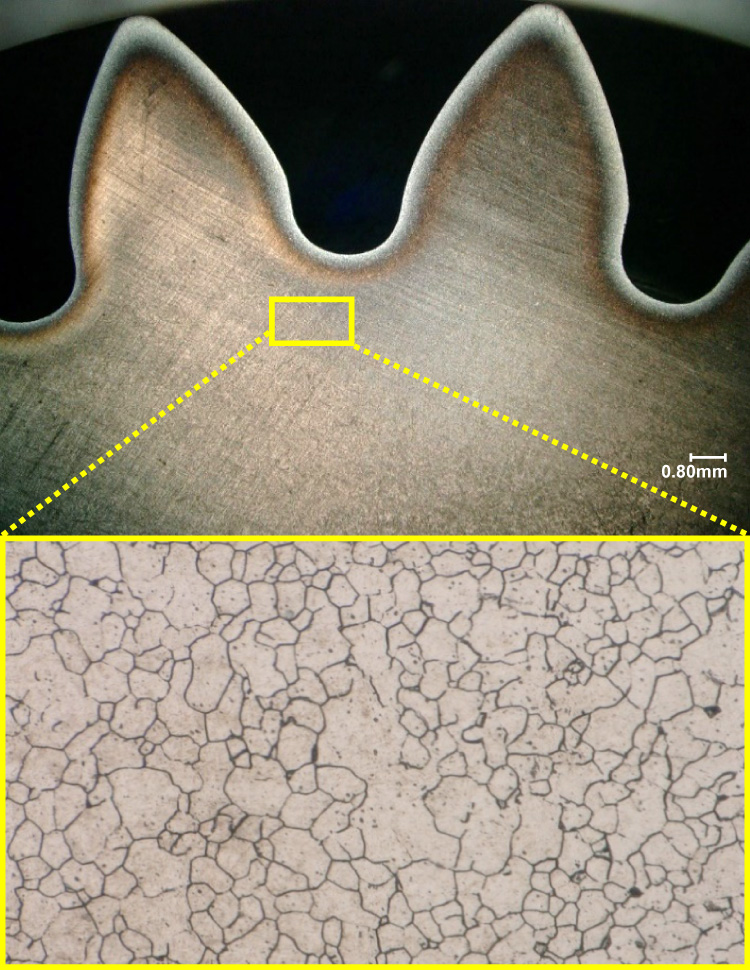

Differences in surface properties between RX and FC KANETA ver.

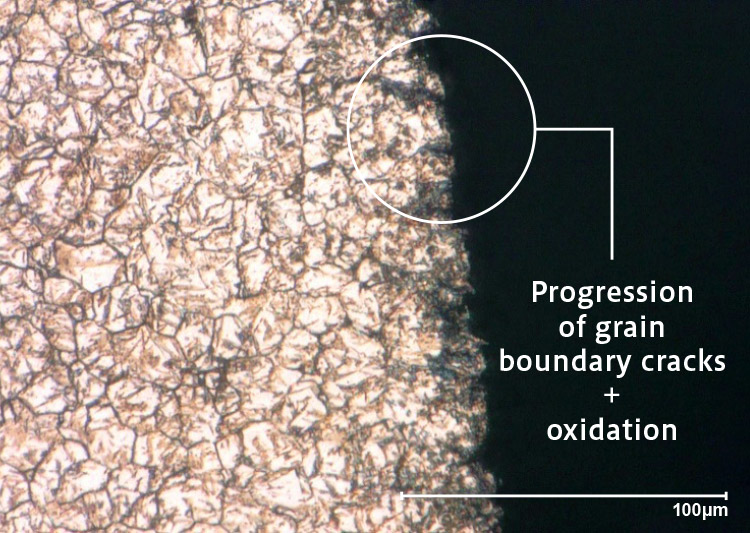

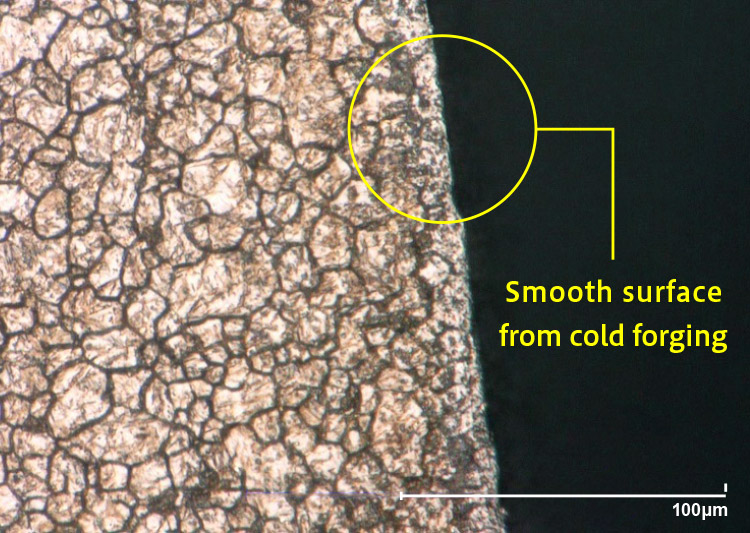

RX method Nital etch

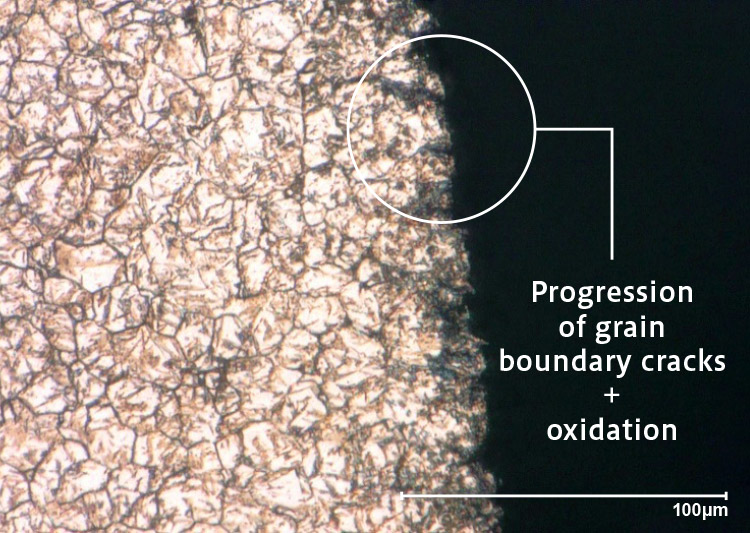

In the case of atmospheric gas carburizing, an oxide film generally called an abnormal surface layer is formed. In the case of cutting surface, cracks occur at the grain boundaries due to shear stress during machining, and active internal oxidation occurs.

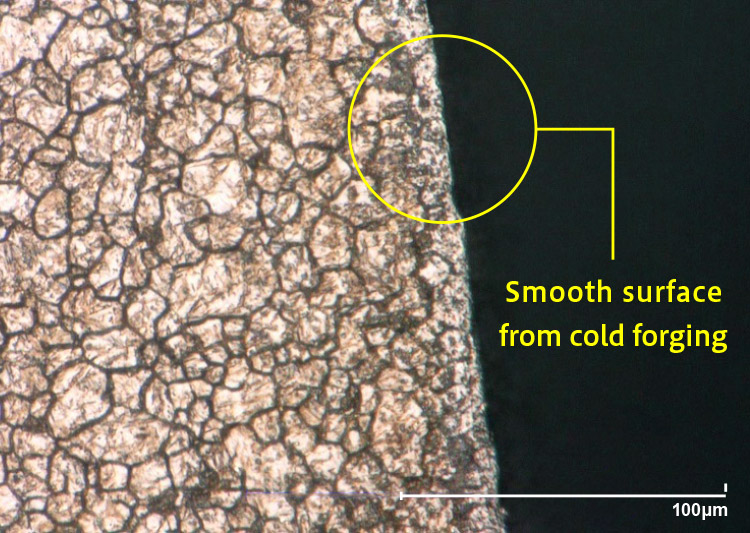

FC method KANETA ver. Picral etch

With precision forging, there are no crystal grains on the surface or cracks at the grain boundaries, so the surface is very smooth. In order to maximize the strength of tooth precision forging, it is necessary to suppress surface oxidation to the utmost extent and to carburize evenly.

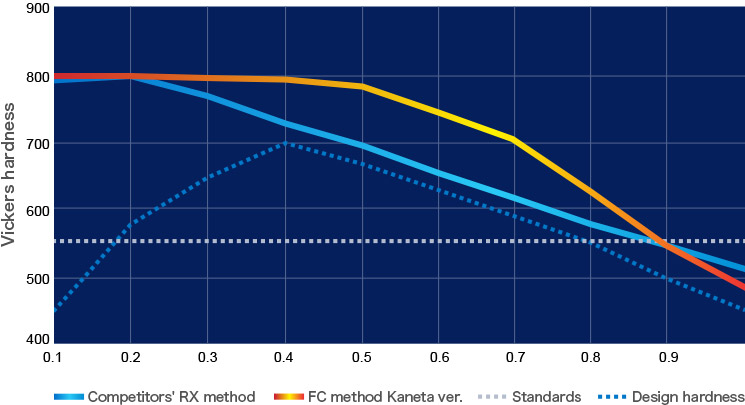

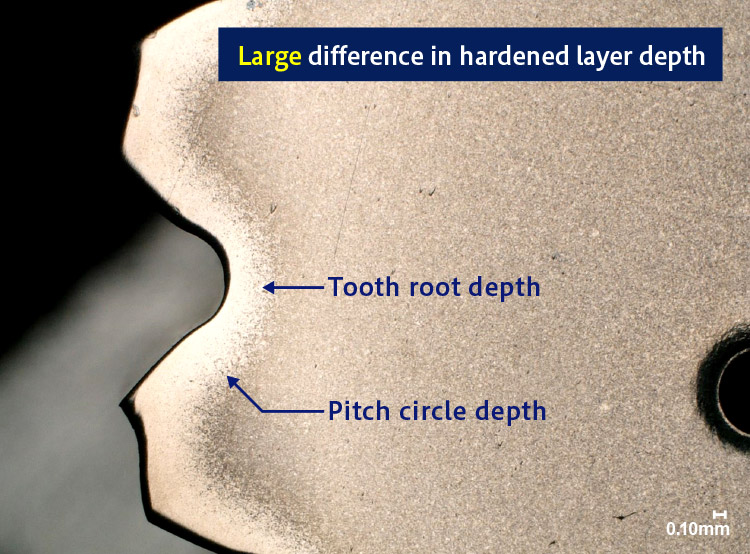

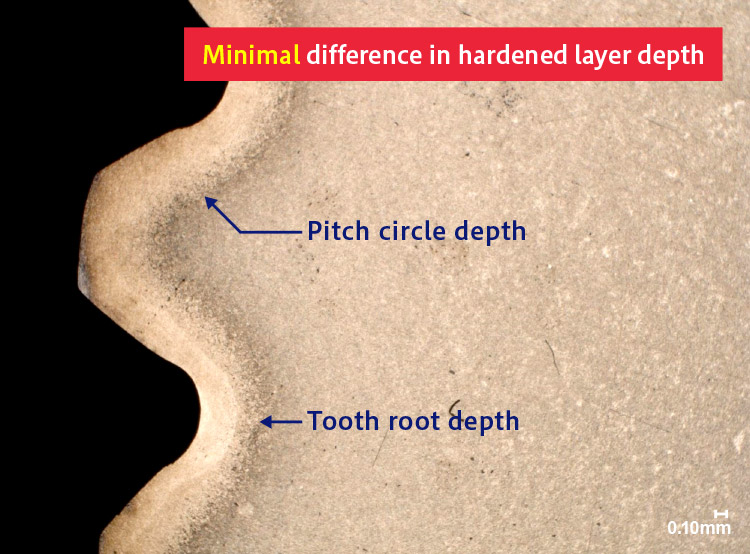

Difference in hardened layer depth variation between FC method KANETA ver. and other methods

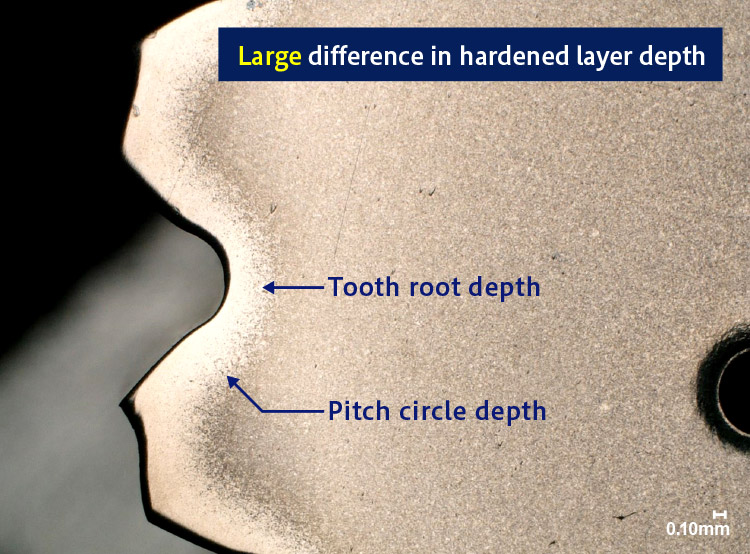

Competitor's RX method

The hardened layer depth in a normal atmospheric carburizing furnace is about 60 to 70 at the tooth root depth if the pitch circle is 100. In other words, the strength of the tooth base is deteriorated, and the surface hardness also decreases due to the internal diffusion of carbon. This is a hardness distribution that is prone to fracture.

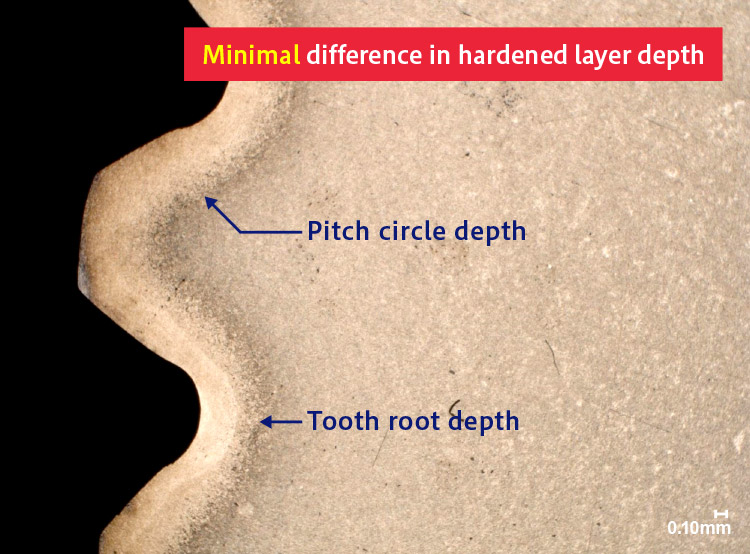

FC method KANETA ver.

With the FC method KANETA ver., it is possible to minimize the variation in hardened layer depth on the pitch circle and at the tooth base. This maintains the hardness of the outermost surface and achieves a high hardness distribution, so the durability is greater than that of normal strength designs.

Effective not only for the surface, but also for bending, twisting, and pitching.

Other company's RX method vs. FC method KANETA ver.

The photo above shows a part that was twisted to breaking starting from a stress concentration point due to the design during durability testing at another company. It was transferred to our company on the condition that there would be no design changes, but the FC method KANETA ver. easily cleared the test. The reason for this is the hardness gradient up to the limit hardness (550Hv). The hardness distribution obtained with the FC method KANETA ver. easily exceeds the hardness profile required by strength design, so it is an effective carburizing and quenching method for bending, twisting, and pitching, meaning downsizing may also be considered.

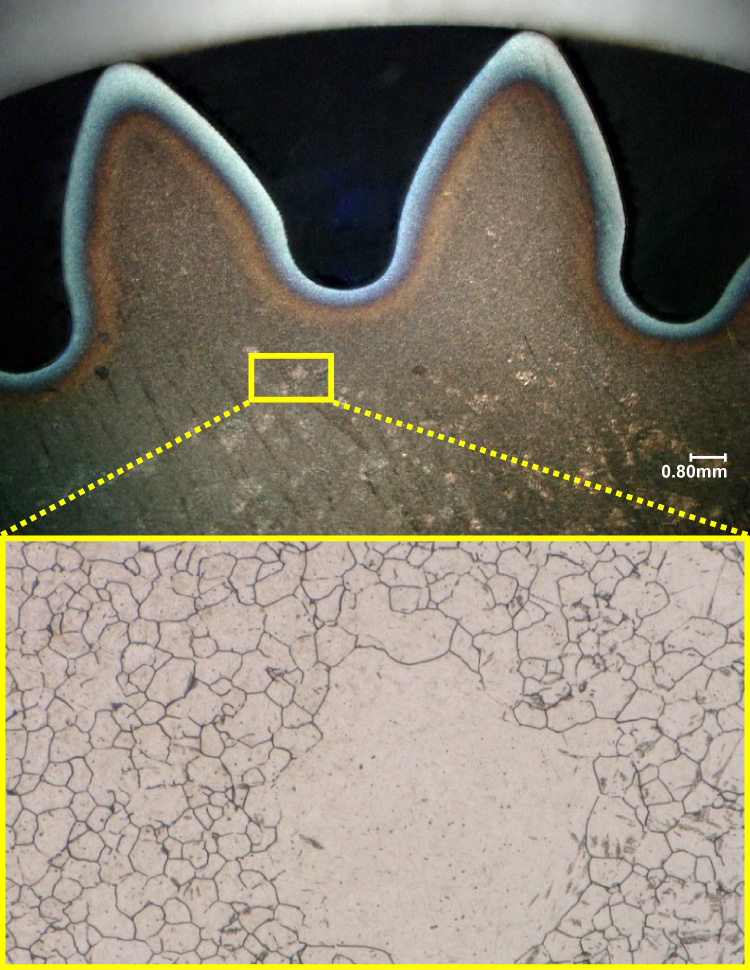

This prevents grain coarsening and neutralizes coarsening energy.

Cold forging not only causes plastic deformation, but also applies strong internal shear stress. Simple carburizing and quenching cause the crystal lattice to break down during processing, and coarsening continues to reduce excess enthalpy. This causes grain boundary and intragranular breakage.

At KANETA, we approached this issue from the perspective of enthalpy theory and have conceived a heat treatment method that prevents grain coarsening.

By conducting a special heat treatment prior to carburizing and quenching, the coarsening energy with a vector is neutralized, and then by conducting FC method carburizing and quenching, the inherent potential of the tooth precision forged helical gears is fully realized.