TECHNOLOGY

We contribute to increase the value of your products

as a development partner involved from upstream processes.

as a development partner involved from upstream processes.

Kaneta Kogyo’s mission is to realize the best match of specifications and manufacturing by participating in our customers’ manufacturing from the design stage.

Start by telling us the product specifications and applications your company requires. We will bring our full technical capabilities to bear in order to realize a product that is competitive on the market, including “VA proposals” that offer advice on customer’s current manufacturing methods in the pursuit of the best balance between quality, cost, and delivery time.

Start by telling us the product specifications and applications your company requires. We will bring our full technical capabilities to bear in order to realize a product that is competitive on the market, including “VA proposals” that offer advice on customer’s current manufacturing methods in the pursuit of the best balance between quality, cost, and delivery time.

Our integrated system enables sophisticated VA proposals.

Kaneta Kogyo covers the complete manufacturing process of shaft products, from forging to machining, heat treatment, and completion inspection, which enables us to offer significant benefits in terms of speed, cost, and quality. For example, consider hollow shafts which are being widely adopted due to increasing need for low weight products. By examining strain during heat treatment, which causes problems due to thinning, we can select the best solution by examining the problem from the perspectives of forging, heat treatment, and machining. In addition, we can flexibly respond to requests for small scale assembly, such as press fitting of bush cover and plugs, which contributes to the efficiency of customer’s processes.

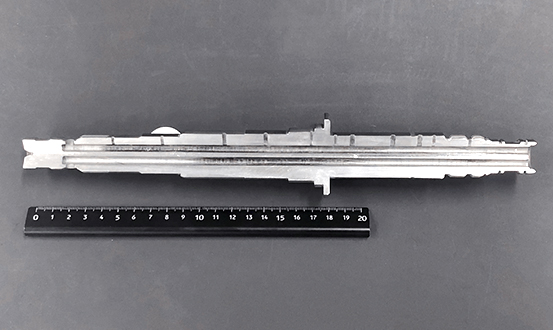

Our excellent deep hole drilling technology meets a wide range of needs.

One of our unique technologies is the high-precision deep hole drilling technology for products with long shafts or complex oil passages. For example, we offer φ5.5, L 280 hole drilling that would be difficult with ordinary machining methods with mass production quality. Based on our knowledge cultivated through the production of shafts thus far, we meet the needs of a wide range of shaft products by selecting the optimum cutting tools and setting the best processing conditions with an intimate knowledge of the materials.

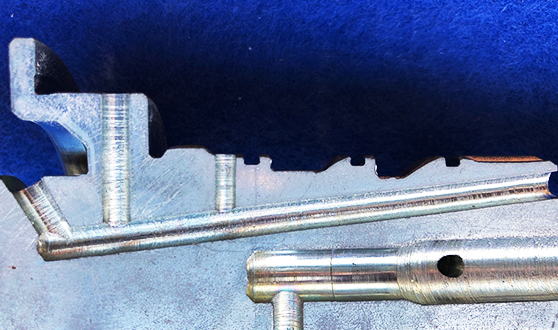

We also offer machining of complex runners, including diagonal hole drilling.

An example of a φ5.5, L278 deep hole drilled with P.C.D8.5.

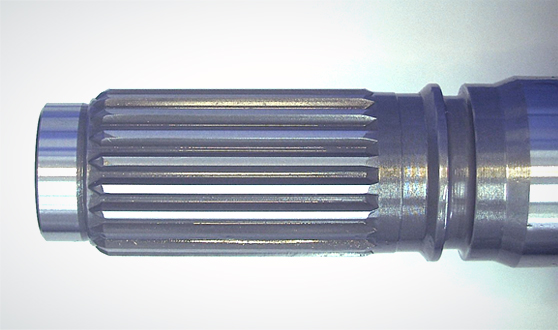

We also specialize in splines with component rolling technology.

Bilge shaped spline tips.

Our proprietary technology can be found in the tip of splines as well. Assembly can be made smoother by making the tips of splines into a shape known as a “bilge” (the bottom of a ship). However, realizing this shape with deformation processing while maintaining the precision of the spline involves significant technical difficulties. Kaneta Kogyo has accumulated knowledge of highly precise component-rolling technology and the best suitable shapes required on the assembly floor through the production of various products including screws and involute splines. We deliver shaft products that help customers improve their own production efficiency.